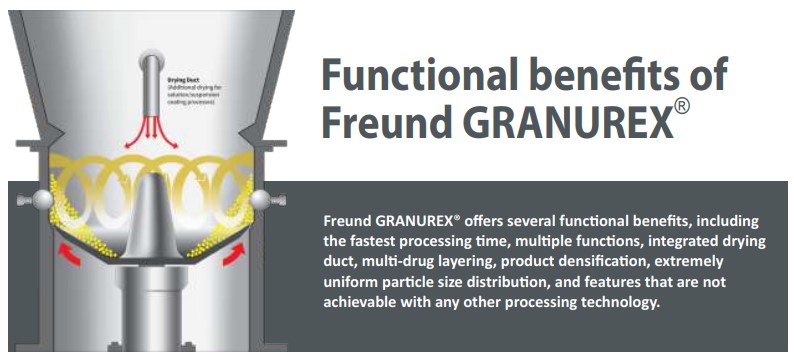

What does GRANUREX® do?

By far, the GRANUREX® is the most powerful pellet/powder processor available in the market place. The applications are endless:

- Pellet Formation: Spherical granulation of powders into spherical granules/pellets (as low as 50 micron).

- Solution/Suspension Coating: Precisely applying a coating onto a core material

- Dry Powder Layering: Rapidly increasing size of pellet by directly applying a powder. The powder could be an API (Active Pharmaceutical Ingredient), a controlled release polymer, or an excipient.

Fastest Process Time

Freund Granurex offers time savings of 50-400%, over traditional solution drug layering. This means:

- Churn out more batches a day.

- Efficiently cater to the markets in time and have a competitive edge over others.

- Lesser manpower and utility costs.

- Avoids laborious monitoring the batches for a week or more (if using Wurster).

- No need of keeping the plant open only for this process, if one is using Wurster coater.

Multiple Functions

The same machine can be used for solution coating as we do in case of Wurster. This means, you can even do functional coat on the pellets after the drug layering is done. Another function is just to do a normal granulation like a fluid bed granulator. However, Granurex works most efficiently (in terms of time) as a dry powder drug layering system. Powder drug layering, solution coating and spherical granulation are possible on Granurex.

Drying Duct

The integrated drying duct is another advantage in Granurex. The preliminary drying can be done in Granurex itself.

Multi Drug Layering

Several drugs can be layered on the NPS in a concentric manner, one after the other, which can enable you to prepare new forms of drug delivery with extended, multiphase drug release profiles.

Product Densification

By virtue of the centrifugal force, weight of the pellets in the bed and the reaction on the pellets the NPS coated with drug gets densified far better than a normal Wurster. This enables us to fill more drug in capsules and make smaller tablet (for MUPS) application.

Other functional benefits

- Reduces or eliminates the need of organic solvents.

- PSD: Extremely uniform particle size distribution, not possible in any other processing technology.

- Interchangeable containers available for drug layering.

- High drug content per pellet. This means the size of the capsule (or MUPS tablets) will be smaller and hence blister/bulk container sizes are smaller leading to lower packing/transportation costs. This is in comparison to extrusion spheronizer.

- Higher shelf life – Obvious advantage of streamlining production.

- Machine range from pilot scale, R&D model to production scale model. Scale up possible

- Models available for different capacity requirements.

- Local service support by trained service team.

- Service backed by process support locally and also from Freund’s process technologists.

- Machine available locally for trials.

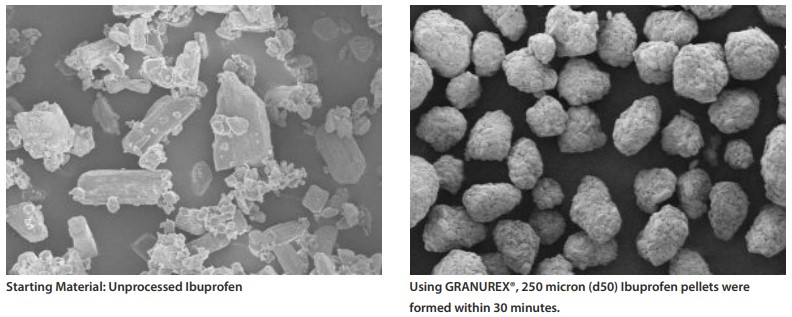

GRANUREX® Case Study 1: Pellet Generation (Spherical Granulation)

Granules produced by the GRANUREX® rotor processor are dense and spherical in shape. The pictures seen as above demonstrate how the GRANUREX® rotor processes Ibuprofen from a 7µm poorly flowing powder to 200µm granules with excellent flow characteristics.

After 30 minutes of processing within a GRANUREX® processor, Ibuprofen pellets were generated seen as above. Ending product characteristics: 250 micron spherical pellets, 0.59 g/cc density, with very good flow properties.

Granules produced by the GRANUREX® rotor processor are dense and spherical in shape. The pictures seen as above demonstrate how the GRANUREX® rotor processes Ibuprofen from a 7µm poorly flowing powder to 200µm granules with excellent flow characteristics.

After 30 minutes of processing within a GRANUREX® processor, Ibuprofen pellets were generated seen as above. Ending product characteristics: 250 micron spherical pellets, 0.59 g/cc density, with very good flow properties.

Case Study 2: Pellet Formation (Powder Coating)

Using a powder feed system, pellets can be dramatically increased in size in a short period of time. The powder applied can be the API, allowing for very heavy loading of active drug onto an existing pellet.

Using a powder feed system, pellets can be dramatically increased in size in a short period of time. The powder applied can be the API, allowing for very heavy loading of active drug onto an existing pellet.

In the picture, the goal was to form pellets with an 80% drug loading with 97% yield. The API material dispensed through the powder feed system was micronized Flurbiprofen. Within a 2 hour period inside the GRANUREX®, the 80% goal was achieved representing in a 400% increase over the original starting sugar pellet. An aqueous binding solution was used.

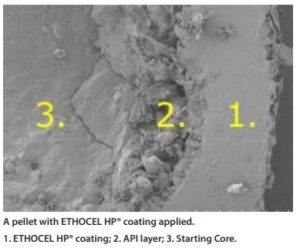

Case Study 3: Dry Polymer Coating

With a GRANUREX® processor, polymer coatings can be applied without the use of organic solvents. Using commercially available polymers, such as Dow’s ETHOCEL HP®, a film coating can be produced onto a pellet (perhaps formed from the previous case studies). A plasticizer solution is applied at the same time the dry polymer is being introduced inside the GRANUREX® chamber.

With a GRANUREX® processor, polymer coatings can be applied without the use of organic solvents. Using commercially available polymers, such as Dow’s ETHOCEL HP®, a film coating can be produced onto a pellet (perhaps formed from the previous case studies). A plasticizer solution is applied at the same time the dry polymer is being introduced inside the GRANUREX® chamber.

In the case study, acetaminophen beads were coated with ETHOCEL HP® to produce a time-released coating. No solvents were used during this process.

Parle Exclusive

Articles

A Lean Approach, by Navdeep Singh Kathuria

To mitigate Regulatory Challenges in Aseptic Manufacturing, by Dr. Subrata Chakraborty

Thoughts on Sustainability Drives by Prabir K Das