TABLET CONSISTENCY & PUNCH LENGTH

A Pragmatic Perspective for European Manufacturers

By Bill Turner

Standards are a part of our lives. Electrical plugs, petrol nozzles, lamp fixtures, and even mobile phone manufacturers have finally agreed on a plug standard that reduces waste and excessive inventory. In the pharmaceutical industry, standards are governed by organizations and institutes such as NSF, ISO, PDA, USP and ASTM, for example. Standards are established for many reasons and touch us in every sector of our lives.

In the pursuit of pharmaceutical excellence, tablet consistency remains a cornerstone of quality assurance. Yet, as many seasoned manufacturers know, achieving uniformity in tablet parameters is a multifaceted challenge. While punch length tolerance often takes center stage in discussions, it is but one of many influential factors. This editorial aims to provide a balanced, persuasive perspective on the true impact of punch length tolerance, especially within the context of European manufacturing standards, and to highlight other critical contributors to tablet consistency.

Formulation Factors: The Foundation of Consistency

Tablet consistency begins with formulation. Variations in active pharmaceutical ingredients (APIs), excipients, particle sizes, shapes, and preparation methods all play pivotal roles. Since tablet dies are filled volumetrically, blend density must remain consistent to ensure uniform weight and thickness. Particle size distribution (PSD) is particularly impactful – smaller particles compress more tightly, increasing compacted density and hardness. However, excessive fines can lead to defects such as sticking and flashing. Batch-to-batch variability in PSD and particle morphology can significantly alter tablet properties, underscoring the need for rigorous formulation control.

and preparation methods all play pivotal roles. Since tablet dies are filled volumetrically, blend density must remain consistent to ensure uniform weight and thickness. Particle size distribution (PSD) is particularly impactful – smaller particles compress more tightly, increasing compacted density and hardness. However, excessive fines can lead to defects such as sticking and flashing. Batch-to-batch variability in PSD and particle morphology can significantly alter tablet properties, underscoring the need for rigorous formulation control.

Tablet Press Factors: Mechanical Precision Matters

The tablet press itself introduces variables that affect consistency. Die table run-out – vertical movement during rotation – can alter fill volume and weight, as the dosing scraper interacts with the die table at a critical moment. Pressure rolls may also exhibit run-out or lack perfect roundness, leading to inconsistent tablet thickness. These mechanical nuances, though often overlooked, warrant attention during troubleshooting and process optimization.

Tooling Tolerance Factors: Rethinking the Punch Length Paradigm

In the arena of solid dose manufacturing, we are aware of the many standards that exist that assure product quality and safety. The standards for tablet compression tooling are relatively new and govern the basic tool configuration for the most common “B” and “D” type tools. The tool standards not only govern the basic tool configuration, such as tool length, punch head configuration, and barrel diameter, but they also affect the mating surfaces, such as the tablet press cams, turret guides, and die pockets. Although a governing body does not govern the latter, tablet press manufacturers respect the tool standards as a guide for engineers tasked with developing tablet presses for optimum performance.

In the arena of solid dose manufacturing, we are aware of the many standards that exist that assure product quality and safety. The standards for tablet compression tooling are relatively new and govern the basic tool configuration for the most common “B” and “D” type tools. The tool standards not only govern the basic tool configuration, such as tool length, punch head configuration, and barrel diameter, but they also affect the mating surfaces, such as the tablet press cams, turret guides, and die pockets. Although a governing body does not govern the latter, tablet press manufacturers respect the tool standards as a guide for engineers tasked with developing tablet presses for optimum performance.

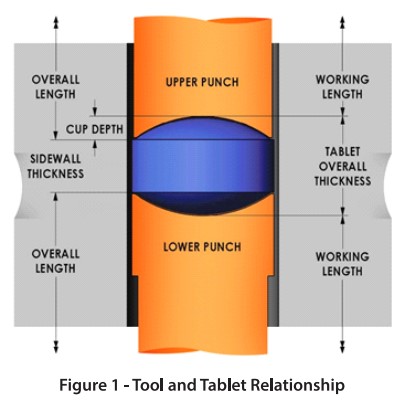

Tooling, particularly punch dimensions, is frequently scrutinized when tablet inconsistencies arise. While variations in working length (W.L.), cup depth (C.D.), and overall length (O.L.) do influence tablet parameters, their impact is often overstated.

European manufacturers typically adhere to a ±0.01mm W.L. tolerance, as per ISO 18084 standards. In contrast, U.S. TSM specifications allow a broader ±0.025mm tolerance. Despite these differences, data shows that even a ±0.02mm tolerance yields tablets well within acceptable weight and thickness ranges.

Data Analysis: Quantifying the Impact of Tolerance

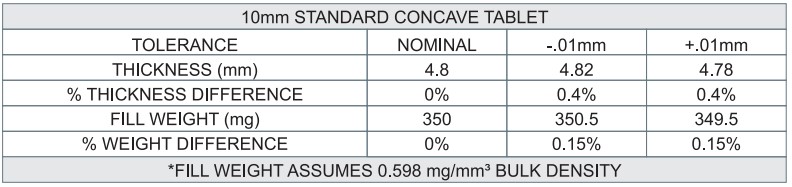

Consider a 10mm diameter standard concave tablet with a target weight of 350mg and thickness of 4.80mm. A ±0.01mm W.L. tolerance results in a thickness variation of ±0.4% and a weight variation of ±0.15%.

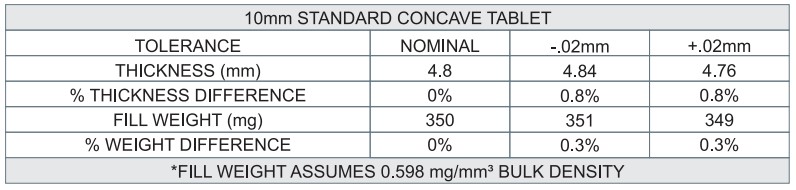

Doubling the tolerance to ±0.02mm increases thickness variation to ±0.8% and weight variation to ±0.3% – still well within specification. These figures represent worst-case scenarios at tolerance extremes; actual deviations are typically smaller due to machining practices.

Practical Insights: Matching and Measuring for Success

Consistency in working length across a punch set is more critical than absolute dimensional values. As punches wear, deviations may occur, but punch sets with ≤0.04mm T.I.R. remain viable for consistent tablet production. Matching reports, which pair punches based on W.L., combine specific upper and lower punches to result in the least possible combined W.L. variation. This minimizestablet thickness deviation and enhances uniformity. These reports can be generated for both new and used tooling using automated inspection systems like Natoli’s TMII.

Measurement Challenges: Precision Comes at a Price

Tighter tolerances demand more sensitive, costly equipment and frequent calibration. Environmental factors, such as temperature, can affect measurements due to thermal expansion and contraction of tool steels. Manufacturers must weigh the benefits of tighter tolerances against the logistical and financial implications of maintaining them.

Tighter tolerances demand more sensitive, costly equipment and frequent calibration. Environmental factors, such as temperature, can affect measurements due to thermal expansion and contraction of tool steels. Manufacturers must weigh the benefits of tighter tolerances against the logistical and financial implications of maintaining them.

Conclusion: A Balanced Approach to Tablet Consistency

Tablet consistency is influenced by a constellation of factors – formulation, press mechanics, and tooling dimensions. While punch length tolerance plays a role, it should not be overemphasized at the expense of other variables. European manufacturers can confidently adopt a ±0.02mm W.L. tolerance, achieving in-spec tablets while optimizing tooling costs and inspection efficiency. A holistic approach, grounded in data and practical insights, is the key to consistent, high-quality tablet production.

About the Author

About the Author

Bill Turner has been with Natoli Engineering for over 46 years, starting at a young age of 21. He is currently the Technical Service Manager for Tooling and Tablets, providing technical assistance to customers and colleagues alike. Prior to that position, he was the Engineering Manager and the primary tablet and tool designer for over 20 years, as well as simultaneously a Technical Customer Service Representative for 20+ years. He educates, trains, and assists Natoli sales and service staff. He leverages these decades of experience into in-house and on-site seminars to the industry in these same topics.