Containment in Process Technology

L.B. Bohle produces solutions for different containment levels and process steps. Its BFC 100 meets the latest containment requirements. Another successful project is the design of a dry granulator from the BRC series. The BRC 100 Containment is proven through the typical BRC attributes.

In the pharmaceutical industry, one term is becoming increasingly important: containment. It describes the process of containing a substance within a defined space, a method that is suitable for protecting operators and the environment in case of high toxicity and product reactivity. At the same time, containment prevents dust, gases or vapours from being released into the environment and contaminating the product.

More than 60 percent of pharmaceutical products are produced as tablets, capsules, lozenges or similar solids. Especially in new products the active pharmaceutical ingredients (APIs) are becoming increasingly more potent. In some markets, the segment for high potency active pharmaceutical ingredients (HPAIs) is growing in the double-digit range, especially driven by oncology medication.

In addition to requirements set by manufacturing guidelines, it is essential that the product is safe for the machine operator and, of course, for the patient. As a result, machine manufacturers such as L.B. Bohle are faced with new challenges in all toxicity classes in which customers want to use plants and processes.

Four projects are examples of this:

The Bohle Film Coaters BFC have been a cutting-edge technology on the market for years and have guaranteed top-quality product processing and high profitability. The BFC Film Coater and its scaled-down version, the BTC, have achieved excellent market penetration.

According to customer specifications, the developers of L.B. Bohle designed a BFC 100 that meets the latest containment requirements.

The containment version of the BFC 100 enables operation in closed driving mode thanks to:

· Automatic nozzle adjustment (stroke and angle)

· Infra-red product temperature measurement

· Charging via a container valve

· The connection for cleaning the container valve and the charging pipe (also available for discharge)

· The connection for drying the container valve and the charging tube

· The sampling lance

· Side doors with inflatable gasket (also standard for BFC)

· The demountable nozzle holder. This results in great advantages when it comes to cleaning.

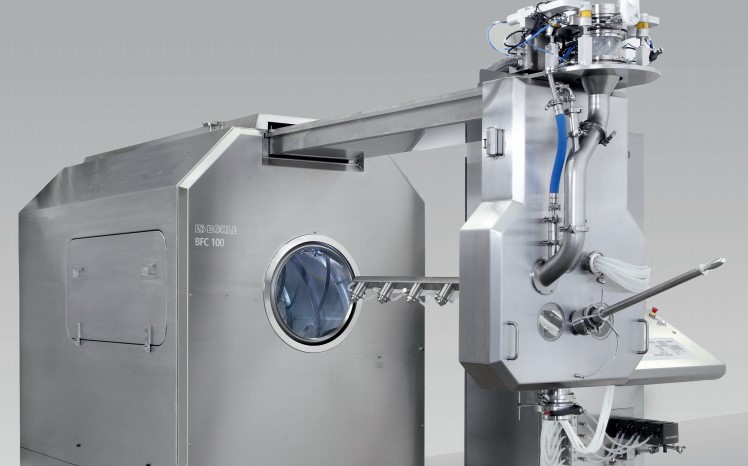

A second successful project is the design of a dry granulator from the BRC series. The dry granulators of the BRC series are already popular in the market due to their flexible set-up or integration into the production process.

A second successful project is the design of a dry granulator from the BRC series. The dry granulators of the BRC series are already popular in the market due to their flexible set-up or integration into the production process.

Continuous dry granulation has been an established process in the pharmaceutical industry for decades and is used not only for products sensitive to moisture or temperature, but also for classic wet granulation because no energy-intensive drying processes are required. This saves high investments in systems and production rooms, resulting in lower costs per batch.

Dry granulation is often the process of choice in particular for high-volume or moisture-sensitive products.

The BRC 100 Containment is proven through the typical BRC attributes. Just like the standard version, the Containment BRC features a state-of-the-art electro-mechanical drive, completely eliminating the need for hydraulics.

In addition, the special version is equipped with the latest and fastest control which enables fully-automated operation. The BRC is very user-friendly and low-maintenance, with very short set-up times.

The highlights of the BRC Containment at a glance:

· Equipped for the containment level OEB 5

· Integrated insulator unit in the compacting unit with corresponding vacuum monitoring

· Glovebox with security prompt for the removal of scabs

· Containment port for the collection of scab samples

· Containment port underneath the sieve unit for the removal of granules

· Convenient access, since no complete insulator unit is installed around the entire compactor

· Residue-free removal of product by integrated WIP equipment (WIP is also integrated in the standard version).

For many years, L.B. Bohle has been known as a supplier of all-in-one solutions and successfully demonstrated this once again in this BRC project. The fully-integrated solution also contains a lifting column and containment flaps for feed-in of the product as well as an integrated containment valve for transferring the granules into the receiving container. Thus, customers have been relieved of some tasks involving the clarification and implementation of interfaces between the system components.

For many years, L.B. Bohle has been known as a supplier of all-in-one solutions and successfully demonstrated this once again in this BRC project. The fully-integrated solution also contains a lifting column and containment flaps for feed-in of the product as well as an integrated containment valve for transferring the granules into the receiving container. Thus, customers have been relieved of some tasks involving the clarification and implementation of interfaces between the system components.

An all-in-one solution for blending, sieving, wet granulation and compressing solids at a facility in Germany was realized for an international global player. The complex system was installed in one room and helped the customer modernizing its manufacturing process. At the same time, the system increases personal protection as well as production capacity.

The key component of the project is the VMA single pot granulator in explosion-proof design including feeding. In addition, the combined mixing and sieving station, which consists of a lifting column with a rotation sieve and the PM 400 container blender. The system is completed by the XL 100 WIPCon tablet press from KORSCH AG as the third module. It is also fed by a lifting column integrated into the automation.

In addition, the combined mixing and sieving station, which consists of a lifting column with a rotation sieve and the PM 400 container blender. The system is completed by the XL 100 WIPCon tablet press from KORSCH AG as the third module. It is also fed by a lifting column integrated into the automation.

Thanks to the use of active and passive valves, the highly complex systems are suitable for containment applications. The single pot granulator as well as the blending and sieving station are intended for installation in EX zone 2/22.

A fully-integrated system for container blending, transfer and milling offers highest flexibility and security for the process. The blender has an extended hoist to enable maximum lifting capability in height. It can pick up containers as well as bins for blending and lifting.

The column to the right holds a special load arm which carries a straight transfer pipe as well as a conical mill. Each in between two active sections of a split butterfly valve.

The column to the right holds a special load arm which carries a straight transfer pipe as well as a conical mill. Each in between two active sections of a split butterfly valve.

This column can swivel underneath a lifted container to serve as a transfer- or milling station under contained conditions. The station has automated controls and includes all interlocks for a semi-automatic operation involving all relevant safety features. It offers full flexibility and can combine all different container sizes for blending-, sieving- and transfer operations. The system covers a fully functional solution with interfunctionality of all components.