Breaking the Misconceptions of Maximum Compression

By John Norman, Mechanical Drafter and Designer, Technical Service Support, Natoli Engineering

It is common for tablet manufacturers to exceed the maximum compression force ratings of their tooling to form a quality tablet. This situation usually arises when an issue with the formulation or powder causes the press operator to exceed the recommended force range of the tooling in an attempt to produce an acceptable product. However, going beyond the prescribed tooling rating may result in premature tool wear or failure and possible damage to the press. With proper formulation development and tablet design, the tablet press operator should be able to manufacture quality tablets without exceeding the tooling’s maximum compression force rating.

Tablet compression tooling manufacturers establish maximum compression force ratings to prolong tool life and avoid premature tool failure. These manufacturers assign a rating to each set of punches that identifies the maximum compression force recommended for that particular set of tooling. Press operators may exceed the recommended force for a short period of time, but if the punches are run continuously at a higher force, the service life of the tooling will decrease and could result in tool failure.

By providing accurate maximum force ratings, tooling vendors help tablet manufacturers protect their punches and tablet press from damage. This article describes the variables that are analyzed by reputable tooling vendors when providing the maximum force rating for their tablet compression tooling. A better understanding of how this rating is calculated will help tablet manufacturers design a tablet that can be efficiently and successfully manufactured.

The Misconception

There is often a misconception among tablet manufacturers regarding the maximum compression force rating for punches and how that rating is determined. The misconception is that the force rating provided by the tooling vendor is determined by only one variable, such as the material of the punches. This, however, is not the case as the calculations to determine a maximum force rating include many variables and any changes to the tablet or tool design could influence this value. With every tool design being custom, the allowable force rating is tailored to each individual application. There is not a common compression force rating that is applicable across a range of products.

Steel selection, heat treatment of tooling, and tablet configuration all play roles in determining the allowable compression force rating assigned to an individual set of tools. The use of Finite Element Analysis (FEA) software has become common among tool vendors to help analyze tooling designs and help provide more accurate maximum compression force ratings.

Choosing the Correct Steel

Steel selection is one of the primary factors in determining the maximum force rating of tablet compression punches. There are many tool steels available, all of which have unique physical attributes benefiting different tableting applications. The two most important material properties in determining compression force are yield strength and impact toughness. Yield strength is the maximum stress a material can withstand before experiencing plastic deformation.

Impact toughness is the maximum energy that a material can absorb from an impact or shock before fracture. These mechanical properties can be found on published data sheets for all typical punch and die steels. Another critical material property to consider when selecting tool steel is the wear resistance. Wear resistance is the ability of the material to withstand the abrasiveness of a product’s granulation. Most tooling vendors offer a large variety of steel choices for punches and dies, enabling them to recommend a steel that is compatible with the compression force required, and combats the abrasive, sticky, or corrosive properties of the granulation being tableted.

When selecting a tool steel, it is important to consider the characteristics of the formulation, the tablet and tool design, and compression force required. Choosing the proper tool steel based on the tableting application is a critical step to prevent problems during production. All steels have a different chemical composition. Standard steels, such as S7 for punches and D3 for dies, provide a good combination of wear-resistance and toughness. If the product is abrasive, tooling manufacturers may recommend using tool steel that can withstand higher wear, such as D2, A2 or DC53 for the punches. For severely corrosive formulations, high-chrome steels, such as 440C or M340 are viable options. High-chrome steels are also used to mitigate sticking issues. When selecting a material for your application, confirm with your tooling vendor that the punches will withstand the force necessary to compress your tablet and combat any anticipated production issues.

During the manufacturing process, the punches are heat treated to transform the tool steel into a hardened state. Reputable tooling vendors know that the heat-treating process is one of the most critical steps in manufacturing high-quality tablet compression tooling. When the punch material hardens, the elements in the alloy of the steel develop their unique characteristic properties of toughness, wear resistance, and corrosion resistance. There are many steps during the heat-treating process that help alleviate the residual stress that arises from machining performed prior to heat treat. Proper elimination of this residual stress in the material allows the steel to withstand a higher compression force and significantly decreases the chance of premature tool failure.

The Importance of Tablet Design

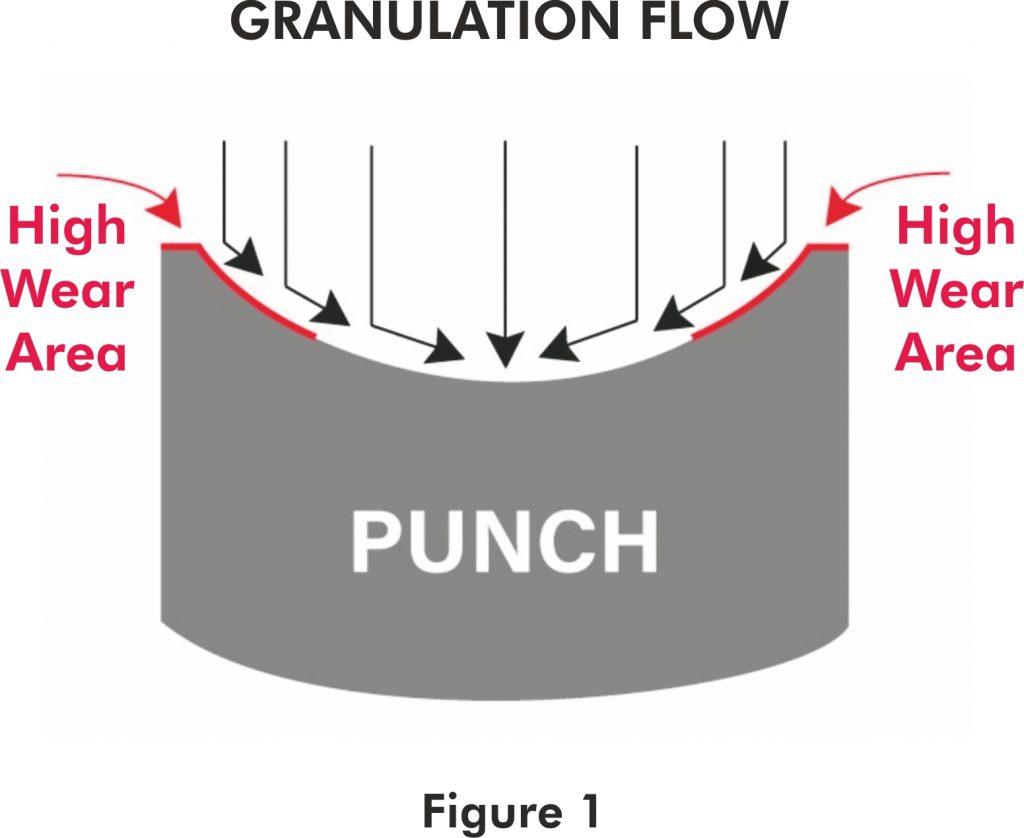

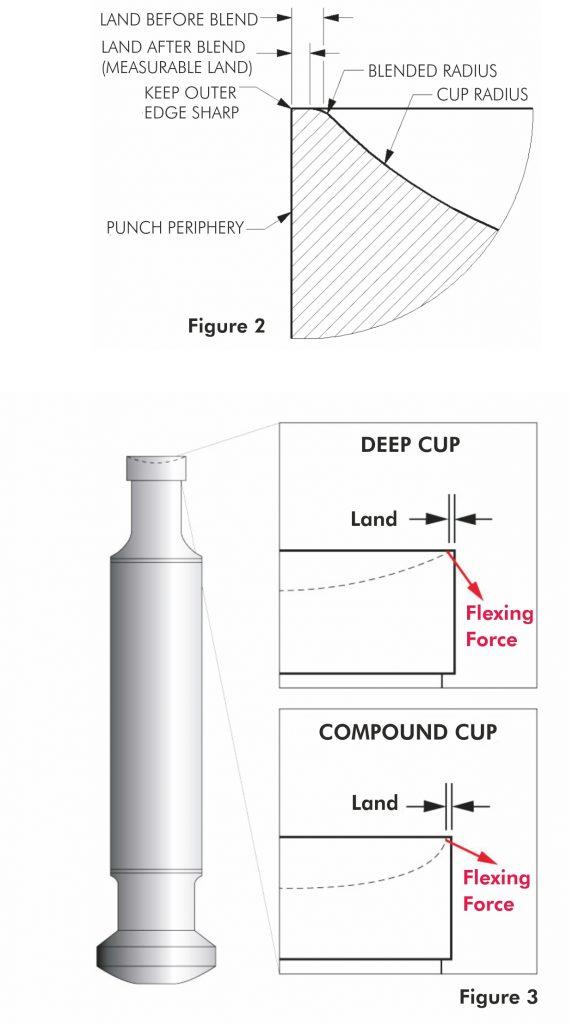

Tablet design characteristics also directly influence the maximum compression force which the upper and lower punches can withstand. Size, cup depth, cup configuration, and land width are the primary tablet design variables that will affect the allowable force rating. Adding land or increasing the land width of an existing design is one way to strengthen tooling and increase the force rating. Land is the area between the edge of the punch cup and the outside diameter of the punch tip. The addition of land to a tablet design not only helps improve the maximum force rating of the punches, but also increases the wear characteristics of the inner edge of the punch cup and reduces the severity of nicks on the outer edge of punch tips as illustrated in Figure 1. When the tablet designer incorporates sufficient land, they have the option to add a generous blend radius at the intersection of the cup radius and land to eliminate any sharp transition between the two surfaces as shown in Figure 2. Land plays a vital role in achieving a higher tip force rating when the tablet design has a deep or compound cup design and is considered necessary on these designs.

Deep cup and compound cup configurations typically result in a steeper slope at the edge of the cup and negatively impact the allowable tip force rating for the tooling. Deep or compound cup configurations, shown in Figure 3, can create near vertical surfaces at the cup edge and the addition of land adds inherent strength to the tooling. The arrows in Figure 3 depict the flexing forces the tooling tip experiences during tablet compression. Compound cup designs have a greater angle of flexing force and result in an overall lower allowable force rating due to the smaller cup radius near the tip edge. Changing a tablet’s cup configuration or shallowing the cup depth can help increase the strength of the tool, increasing the maximum compression force rating. Knowledgeable tablet designers can suggest slight modifications to a tablet design, such as a slight increase in the outer radius of a compound cup, to increase the maximum compression force rating without drastically changing the tablets geometry, function or appearance.

Reputable tooling vendors supply the maximum tip force ratings with all tablet and tooling drawings. These ratings take into consideration that the punch tips will experience wear over time. When calculating the maximum tip force rating, tooling vendors safeguard their tooling, by utilizing a factor of safety (FOS), to extend the service life and prevent premature failure. It is essential to understand that tooling may initially withstand more force than what is recommended, but if operated continuously at a higher force its life may be significantly shortened. Maximum compression force ratings are determined by conducting multiple FEA sets emulating the same force being applied to the tooling as it wears throughout its lifetime. The solid 3D models in Figure 4 depict how tooling design affects the strength of the punch tip.

Figure 4: FEA analysis performed at 30kN of force on an 8mm standard concave cup design. These images illustrate how the amount of land on tablet compression tooling affects the maximum tip force rating. A decrease in land increases stress and can negatively impact the allowable compression force rating. The maximum compression force rating provided by tooling vendors should also take into consideration that tooling experiences a build-up of residual stress, in addition to wear, over its life cycle. It is normal for the maximum compression force a tool can withstand to decrease over time due to residual stresses that build-up inside of the tip during use. With tool wear occurring during each compression event, this also reduces the maximum force the punch tips can withstand over their lifetime. As a punch wears, the maximum compression force that it can withstand is reduced. The compression force that a tool can withstand when producing the first tablet is going to be higher than the force it could withstand when compressing the one millionth tablet. Tooling vendors are capable of providing acceptable tip force ranges for new and/or worn tooling through the use of FEA software. Ask your tooling vendors if their tooling is designed and engineered for continuous high cycle loading.

Micro-Tab Tooling

Micro-tab tooling is gaining popularity in many industries. Understanding the allowable force this type of tooling can withstand is critical. Generally, the term micro-tab tooling refers to tablets that are 4 millimeters (5/32”) in diameter or smaller. The compression force rating when using micro-tab tooling is normally not determined by the cup geometry, but rather the possibility of bending of the very small punch tips.

When designing micro-tab tooling, tool vendors should obtain the maximum fill requirement from the tablet manufacturer and recommend using the shallowest fill cam possible to maintain a tablet that meets all the required parameters. Knowing the maximum size of the fill cam helps the tooling vendor design the best tool configuration for the application. When the selected fill cam is shallower than the standard fill cam for that tablet press, the tooling vendor can design the tooling to have an undercut die, and a shortened lower tip straight to strengthen the lower punch tips as displayed in Figure 5. This tooling design helps increase the allowable maximum compression force rating for micro-tab tips. To utilize this tool configuration, the tablet press will also need to be equipped with effective lower punch retainers or filler plates.

Figure 5: Example of shortened lower punch tips and an undercut die.

The maximum compression force rating provided for a tooling set could be different between tooling vendors. This difference may be explained by vendors having different factors of safety (FOS) built into their force calculations. The FOS is the ratio of the calculated stress to the yield strength of the material. If the tooling has a FOS of two, that means the force applied generates stress in the tool steel that is one-half the yield strength of the material. With all the variables that go into manufacturing high-quality tablet compression tooling, the allowable maximum compression force is dependent on each of them and could change if any of the variables are altered.

The factors that determine the maximum allowable compression force for tablet tooling can vary based on the steel selection, heat treatment process, tablet and tool configuration, and tooling wear. With a better understanding of these elements, tablet manufacturers can establish parameters for their tooling that increases tooling life and prevents premature tooling failure.