Factory of the Future: How Prepared Are We

By Anil Arora

By Anil Arora

Turning the vision of a future-ready pharmaceutical manufacturing facility into reality is no cakewalk. The decision on whether to invest in a fully automated, AI-driven smart factories or stick with labour-intensive, traditional setups in light of changing regulatory requirements, sustainability commitments, workforce transformation, and cost challenges is not for the faint of hearts. A smart manufacturing facility leveraging automation, artificial intelligence, digital twins, and the Internet of Things, offering a flexible, efficient, and sustainable approach all the while aligning with the industry’s cost-sensitive nature may seem like a utopian solution. Nevertheless, “smart factories are changing the journey of a tablet from cradle to grave” is no longer an overstatement today and the prime question, “how prepared are we for it?” should echo through every pharma boardroom and top the list of all business risk playbooks. After all, in an industry where precision is paramount and stakes are sky-high, preparation isn’t optional – it’s survival.

Anil Arora is a strategically driven and innovation-focused operations leader with over three decades of expertise in global pharmaceutical manufacturing, regulatory compliance, and cross-functional team leadership. He has achieved record-breaking regulatory milestones, including 33 ANDA approvals in a single year and the filing of 23 new products, reinforcing a robust pipeline for growth. He led the implementation of India/Asia’s first robotic production line, reducing manpower requirements from 11 to 2 and enhancing productivity and cost-effectiveness. He has extensive regulatory expertise in USFDA, MHRA, TGA, ANVISA, EDQM, and WHO markets, ensuring compliance and excellence in high-stakes, diverse projects. He has served as President (Global Operations), Granules India Limited; Senior Vice President and Global Head of Manufacturing Operations, Dr. Reddy’s Laboratories Limited; Senior Vice President, Global Manufacturing Operations, Zydus Healthcare Limited; Director, India Manufacturing, EPD India, Abbott Healthcare; Head of Production, India, Unichem Laboratories Ltd; and Manager, Production, India, Dabur India Ltd, among others.

The pharmaceutical sector is riding the wave of Pharma 4.0, the fourth industrial revolution tailored for drug production. This revolution integrates cutting-edge technologies such as automation, digitalization, AI, and IoT to enhance production efficiency, ensure compliance, and drive sustainability. According to a 2023 report by Markets and Markets, the global Pharma 4.0 market, valued at $12.9 billion in 2022, is projected to skyrocket to $62.1 billion by 2032 – a staggering fivefold increase in a decade. That’s not pocket change; it’s a testament to the industry’s accelerating digital transformation and a wake-up call for those still on the sidelines.

Industrial Revolution in the eyes of Pharma: The Journey to Smart Manufacturing

The tale of evolution of manufacturing is no less than a sci-fi saga, fuelled by technological advancements and the relentless pursuit of efficiency. From clanking steam-powered machines of the 18th century to today’s AI-driven smart factories, each industrial revolution has reshaped how industries operate – including pharmaceuticals. The pharmaceutical sector starting with apothecaries painstakingly grinding herbs, sailing through deeply rooted manual production methods, now stands on the brink of its most transformative phase yet: Pharma 4.0.

The tale of evolution of manufacturing is no less than a sci-fi saga, fuelled by technological advancements and the relentless pursuit of efficiency. From clanking steam-powered machines of the 18th century to today’s AI-driven smart factories, each industrial revolution has reshaped how industries operate – including pharmaceuticals. The pharmaceutical sector starting with apothecaries painstakingly grinding herbs, sailing through deeply rooted manual production methods, now stands on the brink of its most transformative phase yet: Pharma 4.0.

The Evolution of Industrial Manufacturing

- First Industrial Revolution (Mechanization): The First Industrial Revolution kicked off with mechanized production, boosting output tenfold. For pharmaceuticals, this meant swapping mortar and pestle for machines that churned out basic drugs like aspirin’s precursors. By 1800, Britain’s mechanized textile output had soared by 50 times over pre-industrial levels, setting a precedent for scale. In pharma, this era saw a transition from hand-prepared medicinal formulations to mechanized production of basic drugs. The shift allowed for greater consistency, but processes were still heavily dependent on human oversight.

- Second Industrial Revolution (Mass Production): Fast forward to the late 19th and early 20th century – electricity crackled, and assembly lines roared to life. Henry Ford’s car production slashed assembly time from 12 hours to 90 minutes, and pharma wasn’t far behind. By the 1920s, companies like Eli Lilly were mass-producing insulin, slashing costs and saving millions of lives. Standardized processes made medicines a household name, not a luxury. The global pharmaceutical market, barely a blip in 1900, hit $1 billion by 1930 – an early sign of explosive growth.

Third Industrial Revolution (Automation & IT Systems): Enter the mid-20th century – its computers everywhere! and robotics flexed their mechanical muscles. According to an MIT study from the 1970s, automation cut manufacturing error rates by up to 80%. Pharma embraced digital controls, slashing human oversight in favour of precision. By the 1990s, electronic batch records replaced paper trails, and quality management systems ensured compliance with tightening regulations. Pfizer’s adoption of automated systems in the 1980s boosted production efficiency by 25%, laying the groundwork for today’s smart factories.

Fourth Industrial Revolution (Pharma 4.0): Today, we’re in the thick of the Fourth Industrial Revolution – a dazzling fusion of interconnected systems, where AI, IoT, and digital twins reign supreme. Unlike its predecessors, Pharma 4.0 isn’t just about speed; it’s about intelligence. Real-time data slashes production delays by 30%, per a 2024 Deloitte study, while predictive analytics pre-empts failures.

What is noticeable in each phase of these revolutions is that the time taken for revolutionary changes has drastically decreased over time. The time between revolutions is shrinking – where the first took a century, fourth is unfolding in mere decades. As Bill Gates once said, “We always overestimate the change that will occur in the next two years and underestimate the change that will occur in the next ten.” Pharma’s future is arriving faster than we think. What’s striking is the breakneck pace of change. The “steam age” lingered for generations; now, disruptions hit like lightning. In 2023 alone, 68% of pharma executives surveyed by PwC said they’d ramped up digital investments – a clear signal that agility is the new currency. For manufacturers, it’s adapt or perish.

Pharma 4.0: Not a tweak, but a tectonic shift

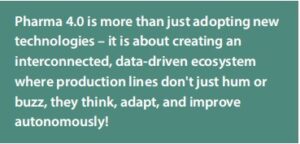

The pharmaceutical industry is undergoing a seismic shift as it moves from traditional manufacturing to a digital-first approach. Pharma 4.0 is more than just adopting new technologies – it is about creating an interconnected, data-driven ecosystem where production lines don’t just hum or buzz, they think, adapt, and improve autonomously! As regulatory demands tighten, drug development timelines shrink, and personalized medicine gains momentum, these advancements are proving to be game-changers in ensuring efficiency,

The pharmaceutical industry is undergoing a seismic shift as it moves from traditional manufacturing to a digital-first approach. Pharma 4.0 is more than just adopting new technologies – it is about creating an interconnected, data-driven ecosystem where production lines don’t just hum or buzz, they think, adapt, and improve autonomously! As regulatory demands tighten, drug development timelines shrink, and personalized medicine gains momentum, these advancements are proving to be game-changers in ensuring efficiency, compliance, and patient safety and for pharma manufacturers, being at the forefront of technological advancements is no more a luxury; it is a lifeline.

compliance, and patient safety and for pharma manufacturers, being at the forefront of technological advancements is no more a luxury; it is a lifeline.

At the heart of this transformation, key technologies that are driving Pharma 4.0 from the frontlines and how these innovations are shaping the pharmaceutical landscape with real-world applications from the industry are explored below:

AI and Machine Learning for Real-Time Optimization

Artificial Intelligence (AI) and Machine Learning (ML) for pharmaceutical sector is basically crunching numbers to save lives! Use of AI and ML is revolutionizing pharmaceutical manufacturing by analysing vast amounts of data in real-time to optimize production processes, reduce waste, and enhance compliance. Data driven insights with AI assistance for batch production optimization, predictive maintenance and quality monitoring are a reality of today. A 2023 McKinsey report on AI in manufacturing noted that leading pharma companies have achieved downtime reductions of 20-40% through predictive maintenance and pegs AI-driven manufacturing improvements at $100 billion annually across industries.

Artificial Intelligence (AI) and Machine Learning (ML) for pharmaceutical sector is basically crunching numbers to save lives! Use of AI and ML is revolutionizing pharmaceutical manufacturing by analysing vast amounts of data in real-time to optimize production processes, reduce waste, and enhance compliance. Data driven insights with AI assistance for batch production optimization, predictive maintenance and quality monitoring are a reality of today. A 2023 McKinsey report on AI in manufacturing noted that leading pharma companies have achieved downtime reductions of 20-40% through predictive maintenance and pegs AI-driven manufacturing improvements at $100 billion annually across industries.

Real pharma world examples:

- Predictive Maintenance: Machine learning algorithms detect early signs of equipment failure, preventing costly downtime.

- AI-driven analytics help to predict potential deviationsin drug production, allowing for immediate corrections.

- Batch Production Optimization: AI-powered analytics adjust production parameters dynamically to improve yield and efficiency.

- Machine learning algorithms help forecast equipment failuresbefore they happen, reducing unplanned downtime.

- Continuous Quality Monitoring: AI-driven analytics track variations in process parameters, ensuring compliance with regulatory requirements.

Digital Twins: Simulating the Manufacturing Process

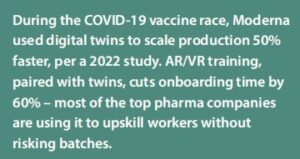

Digital twins create virtual replicas of pharmaceutical production lines, allowing manufacturers to simulate and optimize processes before real-world implementation. This technology enables companies to conduct predictive maintenance, reduce batch failures, and enhance workforce training using AR/VR simulations. A full-fledged digital twin is like a virtual factory mirroring the real one. Digital twins slashed Boeing’s design flaws by 40%; in pharma, they’re just as potent. During the COVID-19 vaccine race, Moderna used digital twins to scale production 50% faster, per a 2022 study. AR/VR training, paired with twins, cuts onboarding time by 60% – most of the top pharma companies are using it to upskill workers without risking batches.

Real pharma world examples:

- Utilization of digital twins was the key driver to accelerate COVID-19 vaccine production, ensuring rapid scale-up without compromising quality.

- Workforce Training with AR/VR:Augmented and Virtual Reality (AR/VR) simulations are used to train employees on complex equipment. This not only helps reduce human errors, but also drastically reduces the time needed to train and onboard an employee at the shop floor.

- Process Simulation:Digital twins help companies simulate drug manufacturing processes to identify bottlenecks and improve efficiency.

Robotics and Automation: Reducing Human Error

Automation is redefining pharmaceutical manufacturing by minimizing manual intervention and increasing precision that human can never achieve. Robots reduce the risk of contamination to a great extent. After all, robots don’t sneeze in cleanrooms.

Real pharma world examples:

- Collaborative Robots (Cobots): Companies have deployed cobots to assist human workers in handling delicate processes, such as aseptic filling, packing etc.

- Automated Material Handling: Autonomous guided vehicles (AGVs) are a reality of warehouses today, to transport raw materials, optimizing inventory management.

- AI-Powered Quality Control: Vision systems inspect tablets and vials for defects, ensuring batch consistency. Takeda Pharmaceuticals has integrated AI-powered visual inspection to detect even the smallest irregularities.

IoT & Real-Time Data Connectivity

The Internet of Things (IoT) can be referred to as the nervous system of smart factories. The “think and respond” part of connected devices in the factories of the future can be attributed directly to IOTs. Sensors track everything – temperature, humidity, you name it – which can significantly cut environmental failures by enabling pharmaceutical manufacturers to achieve real-time visibility across production facilities. This helps in achieving unparalleled productivity and quality compliance. IoT-driven predictive maintenance enhances equipment uptime by providing real-time insights into the mechanical stability of critical components and monitoring wear and tear, enabling proactive maintenance and reducing unexpected failures.

The Internet of Things (IoT) can be referred to as the nervous system of smart factories. The “think and respond” part of connected devices in the factories of the future can be attributed directly to IOTs. Sensors track everything – temperature, humidity, you name it – which can significantly cut environmental failures by enabling pharmaceutical manufacturers to achieve real-time visibility across production facilities. This helps in achieving unparalleled productivity and quality compliance. IoT-driven predictive maintenance enhances equipment uptime by providing real-time insights into the mechanical stability of critical components and monitoring wear and tear, enabling proactive maintenance and reducing unexpected failures.

Real pharma world examples:

- Environmental Monitoring:Smart sensors embedded across production lines and cleanrooms enable real-time monitoring of environmental conditions, including temperature, humidity, and air quality.

- Blockchain for Supply Chain Transparency:Blockchain technology is enhancing supply chain transparency, preventing counterfeit drugs from entering the market. Predictive maintenance powered by IoT reduces downtime and improves Overall Equipment Effectiveness (OEE).

- Predictive Maintenance & Smart Logistics:IoT-driven predictive maintenance minimizes unexpected failures, while automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) enhance material flow efficiency.

Cloud Computing & Data Analytics

The shift to cloud-based platforms has enabled pharmaceutical companies to centralize data storage and leverage AI-driven insights for process optimization. Centralized, cloud-based data availability and analytics can slash decision making times. Real-time analytics backed by AI support faster decision-making, regulatory compliance, and remote monitoring of production sites.

Real pharma world examples:

- AI-Driven Insights for Compliance & Efficiency:Cloud-based analytics to enhance process optimization and meet stringent compliance requirements.

- Centralized Data Storage & Processing:Cloud platforms are used by pharma giants to manage regulatory data efficiently.

Pharma 4.0 is not a distant future – it is happening now. By integrating AI, IoT, robotics, and digital twins, pharmaceutical manufacturers are enhancing efficiency, ensuring drug safety, and optimizing the entire value chain. Those who embrace this digital transformation will lead the industry into a new era of innovation, while those who resist risk being left behind.

Smart Pharma & Regulatory call for revolution

The pharmaceutical industry is undergoing a profound transformation, not just in how drugs are manufactured but also in how they are regulated and inspected for quality. The days of relying on dusty binders to store process data and batch information are fading fast. The traditional regulatory framework, once heavily reliant on manual documentation and reactive compliance, has been forced to evolve in response to technological advancements, increasing product complexity, and rising patient safety expectations.

The pharmaceutical industry is undergoing a profound transformation, not just in how drugs are manufactured but also in how they are regulated and inspected for quality. The days of relying on dusty binders to store process data and batch information are fading fast. The traditional regulatory framework, once heavily reliant on manual documentation and reactive compliance, has been forced to evolve in response to technological advancements, increasing product complexity, and rising patient safety expectations.

Regulatory agencies like the FDA (U.S.), EMA (Europe), MHRA (UK), and CDSCO (India) are shifting their focus toward real-time, digitalized oversight, ensuring that every step of a drug’s lifecycle –from development to distribution – is recorded, auditable, and transparent. This shift is not just about improving compliance but about making pharmaceutical manufacturing more resilient, efficient, and aligned with modern technologies.

The Evolution of Regulatory Compliance: A Timeline of Change

To understand the urgency of this transition, let’s examine how regulatory expectations have evolved over the last two decades:

20 Years Ago (~2005): The times of reactive compliance

A drug manufacturer in 2005 would maintain stacks of paper-based batch records, which an auditor would manually review. It wouldn’t be wrong to say that any regulatory audits back in the day was a paper chase! Any discrepancies could take weeks to investigate, often delaying drug approvals and shipments. Manual reviews dragged on for weeks – time pharma couldn’t afford when lives hung in the balance. A single batch record could span 1,000 pages, with errors costing millions in recalls for the company.

Key features of regulatory expectation of the era are as follows:

Key features of regulatory expectation of the era are as follows:

- Regulatory compliance was reactive, relying on extensive paperwork and post-production quality inspections.

- Batch records and validation reports were manually recorded, making audits time-consuming and prone to human error.

- Manufacturing deviations were identified retrospectively, often leading to costly recalls and regulatory warnings.

10 Years Ago (~2015): The time of scrutiny on data integrity and process traceability

Pick-up any warning letters from around 2015s to review the trend of nature of observations from the warning letters issued. It would highlight data integrity violations, issues with traceability of data etc. Such incidents pushed companies to invest in electronic documentation to ensure tamper-proof record-keeping. The key regulatory expectations changed during this period and focused on the below points:

- Regulators began focusing on data integrity, requiring pharmaceutical firms to demonstrate the accuracy, security, and traceability of manufacturing records.

- Implementation of electronic batch records (EBRs) and laboratory information management systems (LIMS) started gaining momentum.

- The FDA’s ALCOA+ principles (Attributable, Legible, Contemporaneous, Original, Accurate) were introduced to ensure data reliability in pharmaceutical manufacturing.

5 Years Ago (~2020): Automation & Real-Time Process Control

This is the era when the global pandemic Covid-19, flipped the scripts of regulatory expectations. During the pandemic, the need of digital records, real-time video feeds, and cloud-based audit trails were greatly felt by the regulatory agencies like the FDA and EMA when they conducted remote inspections instead of physical site visits. This forced many manufacturers to accelerate their digital transformation strategies. Automation adoption began with electronic batch records (EBMRs), Manufacturing execution systems (MES), and Process analytical technology (PAT) tools.

Key features/expectation of the period are:

- Regulatory agencies began encouraging automation in quality control, reducing reliance on manual inspections.

- The COVID-19 pandemic accelerated the need for remote auditing and digital quality management systems (QMS).

- Adoption of Manufacturing Execution Systems (MES), Electronic Batch Manufacturing Records (EBMRs), and Process Analytical Technology (PAT) increased significantly.

- Real-time monitoring of critical process parameters (CPPs) and critical quality attributes (CQAs) became standard to ensure product consistency.

Present Day: Fully digitalized, AI- driven compliance

AI isn’t just the buzzword today for the software and IT industries – Pharma is also gearing up in this direction to harness the full potential of this disruptive technology. The integration of AI in pharmaceutical manufacturing, quality assurance, and regulatory compliance is now more than an innovation – it’s a necessity.

You might be surprised to learn that in 2025, the FDA has already issued several draft guidance documents to the pharmaceutical industry, emphasizing the right use of AI. This is an indicator that AI has already taken the driver’s seat of pharma revolution. Notably, one of the most significant regulatory updates is the FDA’s guidance on the “Use of Artificial Intelligence to Support Regulatory Decision-Making for Drug and Biological Products.” This guidance provides clear recommendations on how AI can be leveraged to generate data and insights that support regulatory decision-making regarding safety, efficacy, and quality. It encourages the pharmaceutical industry to utilize machine learning, deep learning models, and AI-driven analytics to enhance drug manufacturing and quality control, ensuring higher compliance standards.

You might be surprised to learn that in 2025, the FDA has already issued several draft guidance documents to the pharmaceutical industry, emphasizing the right use of AI. This is an indicator that AI has already taken the driver’s seat of pharma revolution. Notably, one of the most significant regulatory updates is the FDA’s guidance on the “Use of Artificial Intelligence to Support Regulatory Decision-Making for Drug and Biological Products.” This guidance provides clear recommendations on how AI can be leveraged to generate data and insights that support regulatory decision-making regarding safety, efficacy, and quality. It encourages the pharmaceutical industry to utilize machine learning, deep learning models, and AI-driven analytics to enhance drug manufacturing and quality control, ensuring higher compliance standards.

Companies that have implemented an AI-powered root cause analysis system and automated document drafting software have claimed reducing batch rejections. A notable example involves a leading Contract Development and Manufacturing Organization (CDMO) that faced a 25% batch rejection rate, resulting in an annual revenue loss of €6 million. By adopting an AI-driven multivariate root cause analysis, the company increased its right-first-time batches from 70% to over 90%, marking a substantial improvement in process robustness.

The FDA has recognized the potential of AI in enhancing quality control within the pharmaceutical industry. In December 2024, the agency finalized recommendations aimed at simplifying the approval process for medical devices that utilize artificial intelligence. These guidelines allow manufacturers to implement updates to AI-enabled devices without resubmitting extensive documentation, thereby streamlining regulatory approval and encouraging the adoption of AI-driven quality control measures. This aligns with FDA’s push for AI-driven quality control, making compliance more dynamic and proactive.

Other key advancements shaping regulatory expectations in 2025 include:

Continuous Process Verification (CPV) powered by AI, which ensures that every batch meets stringent quality parameters without the need for retrospective validation.

Blockchain-enabled traceability, securing the pharmaceutical supply chain and reducing the risk of counterfeit drugs.

AI-driven risk assessment models, which predict compliance risks and trigger corrective actions before regulatory violations occur.

AI-driven risk assessment models, which predict compliance risks and trigger corrective actions before regulatory violations occur.

Cybersecurity integration into pharmaceutical IT infrastructure, ensuring data integrity and protection against cyber threats.

This rapid evolution in regulatory expectations means that pharmaceutical manufacturers must move away from traditional, paper-based processes and embrace cutting-edge technologies. As regulatory expectations continue to evolve, pharmaceutical manufacturers must future-proof their operations by adopting smart, data-driven technologies. With regulatory bodies like the FDA actively guiding the industry toward AI adoption, digital transformation in Pharma 4.0 is no longer optional – it is the new standard for compliance, efficiency, and sustainability.

Challenges in Traditional Manufacturing & The Need for Smart Solutions

The pharmaceutical industry has historically relied on conventional manufacturing techniques, which, while effective in their time, now struggle to keep up with the rapidly evolving demands of global healthcare. Traditional manufacturing methods are often slow, inflexible, and prone to inefficiencies, making it difficult to maintain high product quality while meeting stringent regulatory standards. In an era where real-time data, automation, and AI-driven decision-making are redefining industrial operations, pharma must move beyond legacy systems to embrace smart manufacturing solutions.

Smart factories, powered by automation, real-time monitoring, AI, and IoT, address key challenges that have long plagued traditional pharmaceutical production. Below are some of the most critical pain points of legacy manufacturing systems and how smart technologies are stepping in to resolve them.

1. Lack of Process Transparency

The challenge:

Traditional pharmaceutical manufacturing relies heavily on manual tracking of production processes.

This means that critical quality and efficiency metrics are often recorded on paper or in siloed digital systems, leading to:

Delays in issue identification (e.g., contamination, incorrect formulation, equipment failure).

Inefficiencies due to poor real-time visibility across the production floor.

Bottlenecks caused by reactive rather than proactive problem-solving.

The Smart Solution:

Real-time Data Capture: AI-powered process monitoring systems provide real-time visibility into each stage of drug production, allowing manufacturers to detect deviations immediately.

IoT Sensors for Live Tracking: Smart factories use IoT-enabled sensors to track temperature, humidity, and equipment performance, reducing the risk of product loss due to environmental factors.

Predictive Analytics: AI models analyze vast datasets to predict inefficiencies before they disrupt production, ensuring continuous optimization.

Pharmaceutical companies have already integrated an IoT-based manufacturing execution system (MES), reducing production bottlenecks by 40% and improving batch cycle times.

2. Compliance & Quality Risks

The Challenge:

Ensuring regulatory compliance in pharmaceuticals is highly complex and document-intensive. Traditionally, compliance relies on manual documentation, which is:

Prone to human errors and missing data points.

Time-consuming, delaying audits and regulatory approvals.

Difficult to trace, making process deviations hard to investigate.

The Smart Solution:

AI-Driven Regulatory Compliance: Automated documentation systems generate, track, and validate data in real time, eliminating manual errors.

Blockchain for Audit Trails: Distributed ledger technology ensures tamper-proof records, making compliance audits faster and more reliable.

Automated Batch Release Processes: AI-driven real-time quality control systems allow for continuous monitoring and auto-approval of compliant batches.

AI-powered batch verification has helped pharmaceutical companies cut regulatory approval times by 35%, enabling faster market access for life-saving drugs.

3. Limited Production Flexibility

The Challenge:

Pharmaceutical manufacturers using traditional batch production methods often struggle with rigid processes that make it difficult to:

- Adjust quickly to fluctuating market demand (e.g., vaccine surges during pandemics).

- Scale up or down efficiently without wastage and high costs.

- Implement personalized medicine production due to inflexible systems.

The Smart Solution:

The Smart Solution:

Continuous Manufacturing: Unlike traditional batch production, continuous manufacturing ensures that raw materials are processed in a non-stop flow, improving efficiency and reducing costs.

AI-Powered Demand Forecasting: AI models predict market demand trends, allowing companies to adjust production accordingly.

3D Printing of Personalized Medicines: Smart pharma is experimenting with on-demand drug manufacturing to cater to patient-specific needs.

Leading pharmaceutical companies have adopted continuous manufacturing, cutting production time for essential drugs by 50% and reducing material waste by nearly 30%.

4. Workforce Challenges & Skill Gaps

The Challenge:

As automation and AI reshape pharma manufacturing, the workforce must adapt to new skill requirements. Challenges include:

Skill Gaps: Employees trained in traditional methods may lack expertise in digital systems.

Resistance to Change: Long-time workers may be hesitant to transition to AI-assisted workflows.

Training Bottlenecks: Upskilling large workforces takes time, impacting operational continuity.

The Smart Solution:

Augmented Reality (AR) & Virtual Reality (VR) Training: AR/VR tools provide immersive training, allowing workers to learn new processes in a risk-free virtual environment.

AI-Powered Learning Platforms: Intelligent training modules assess individual skill levels and tailor learning programs accordingly.

Human-Machine Collaboration: Cobots (collaborative robots) work alongside employees, reducing manual workload while enabling human oversight.

Building the Pharma Facility of the Future: Must-Have Technologies

The pharmaceutical facility of the future is no longer just a production site; it is a dynamic, intelligent, and interconnected ecosystem driven by automation, AI, IoT, and digital twins. These advanced facilities are designed to be adaptive, transparent, and sustainable, ensuring seamless integration of regulatory compliance while optimizing production efficiency. By leveraging real-time data, predictive analytics, and modular production capabilities, pharmaceutical manufacturers can create a highly flexible and scalable environment that meets the evolving needs of the industry.

However, this transformation is not just about upgrading technology – it’s about reshaping the entire pharmaceutical value chain to enhance drug quality, reduce costs, and drive innovation.

As companies stand at the crossroads of deciding whether to invest in advanced technologies, a pragmatic approach is essential. A quick litmus test for pharmaceutical firms is to evaluate whether a specific use case is critical to their operations. Since only a handful of these technologies are mature enough to seamlessly integrate with existing legacy systems, organizations must carefully assess:

- If the technology is mature enough for deployment in their environment?

- If the investment in this technology is strategically critical for long-term growth and compliance?

By conducting this evaluation, pharmaceutical companies can make informed decisions that align with both their business objectives and regulatory mandates, ensuring that their transition toward Pharma 4.0 is both sustainable and impactful. This evaluation, based on a sample size of 113 respondents, is well illustrated in a study conducted by BCG on the outlook and digital maturity of the healthcare sector, as shown in the image below. A quick glance at the study reveals that the majority of respondents consider cybersecurity to be mature enough in the current landscape to justify investment, followed closely by cloud platform enablement and technology modernization. Pharmaceutical companies can use this insight to assess their specific needs, investment capabilities, and the maturity of digital technologies to ensure seamless integration when making future investment decisions.

Key considerations for pharmaceutical companies to establish a strong foundation and kickstart their digital transformation journey:

Key considerations for pharmaceutical companies to establish a strong foundation and kickstart their digital transformation journey:

The transition to smart pharmaceutical manufacturing is not without its hurdles. Legacy systems, regulatory complexities, and operational resistance have traditionally slowed the adoption of Industry 4.0 technologies. However, innovative solutions can address these challenges and drive a smooth transformation toward a future-ready pharmaceutical landscape.

1. Fungibility: A Flexible, Future-Proofed, Adaptive Plant

One of the biggest obstacles in traditional manufacturing is rigid infrastructure that struggles to adapt to changing demands. Future-proofing facilities with Generative AI-designed layouts can enable scalable, flexible production environments that evolve with demand shifts. Key elements include:

Modular production lines that enable quick process changes and adjustments.

Scalable communication & networking facilities to ensure seamless data exchange.

AI-driven optimization for energy efficiency, space utilization, and workflow improvements.

2. Automation & Transparency of Material Flow

Manual processes introduce inefficiencies, errors, and compliance risks. Automating material handling and inventory tracking ensures real-time transparency across the supply chain. Pharma companies can ensure quick benefit from:

- Automated dispensing & material handling to improve safety, minimize human intervention, and enhance process efficiency.

- Automation of loading, unloading, packing and similar repeating activities in their production lines.

3. Scenario Testing with Digital Twins

Before making large-scale investments, virtual factory models allow pharma companies to test and refine their processes digitally. Digital twins simulate real-world conditions and optimize manufacturing strategies by:

Testing process improvements before real-world implementation, reducing trial-and-error costs.

Ensuring regulatory compliance by validating changes in a virtual environment before deployment.

4. Strategic Steps for Adoption

To successfully implement these advanced technologies, pharmaceutical companies must take a proactive approach:

Strategic Partnerships: Collaborate with technology providers specializing in AI, IoT, and automation.

Regulatory Engagement: Work closely with agencies like the FDA and EMA to ensure compliance with evolving digital regulations.

Industry 4.0 Adoption Roadmaps: Develop phased digital transformation strategies to transition smoothly while minimizing operational disruptions.

Final Thoughts: The Road to Smart Pharma

The pharmaceutical industry stands at a defining moment. With rapid advancements in technology, increasing regulatory expectations, and evolving patient needs, the sector can no longer afford to rely on outdated manufacturing methods. The transition to smart factories isn’t just about adopting new technologies – it’s about redefining how medicines are produced, ensuring higher quality, greater efficiency, and better accessibility for patients worldwide. Pharma 4.0 represents an era where automation, AI, and real-time data insights drive agility, sustainability, and innovation. Companies that embrace these changes today will lead the industry tomorrow, gaining a competitive edge while future-proofing their operations against ever-changing global demands. The transition should focus on improving efficiency and scalability, enhancing regulatory compliance, reducing manufacturing costs, support sustainability goals and enable personalized medicine.

The question for pharma manufacturers is no longer “if” they should invest in smart factories, but “when”. Those who embrace this change today will not only lead the industry forward but will also drive better patient outcomes, ensure global healthcare stability, and solidify their competitive edge in an increasingly digital world.“Healing is a matter of time, but it is sometimes also a matter of opportunity” – today, that opportunity is digital.