‘India has got the appetite; it is the fastest adopter of continuous coating technology’

Brian O’Hara

“Engaging with Indian manufacturers is always a heartening experience. Their keen interest and receptiveness to advanced technology makes them one of the fastest adopters of continuous coating technology in the world. India is among my favourite destinations, and I want to give them the best that they deserve.”

“Engaging with Indian manufacturers is always a heartening experience. Their keen interest and receptiveness to advanced technology makes them one of the fastest adopters of continuous coating technology in the world. India is among my favourite destinations, and I want to give them the best that they deserve.”

– Brian O’Hara, President, O’Hara Technologies

Since its inception in 1976 by founder Mr. Gil O’Hara, O’Hara Technologies has been guided by a singular vision: to innovate and elevate tablet coating technology.

Today, this legacy is carried forward by Mr. Brian O’Hara, the company’s president, whose entrepreneurial foresight has transformed O’Hara Technologies into a global leader in the tablet coating industry.

His philosophy is clear and unwavering: “Innovation is not optional, it’s our responsibility. Our goal has always been to listen to the industry, anticipate its needs, and create a more efficient manufacturing environment.”

This spirit of innovation finds strong resonance in India. Recognized globally as the “Pharmacy of the World,” India ranks as the third-largest pharmaceutical industry by volume.

“Engaging with Indian manufacturers is always a heartening experience. Their keen interest and receptiveness to advanced technology makes them one of the fastest adopters of continuous coating technology in the world. India is among my favourite destinations, and I want to give them the best that they deserve,” says Brian O’Hara.

O’Hara Technologies is one of the unique manufacturers that focus primarily on tablet coaters. This dedication has allowed the company to continuously bring innovation and technological advancement to the tablet coating technology.

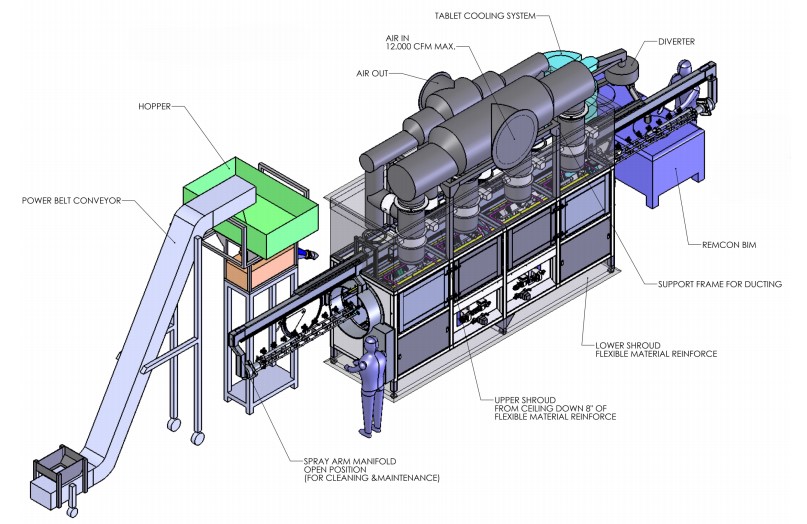

“It has been a committed effort of over 16 years to develop and master the technology before we finally presented the continuous coaters to the industry,” recalls Brian O’Hara. He proudly notes that it’s not just a single model they offer: “We have a family of models ranging from a 30 kg capacity to a 1200 kg commercial manufacturing model.”

While infrastructure is critical, Brian emphasizes that “it’s the people that matter the most.” His team is made up of highly experienced engineers who bring both expertise and passion to their work.

Jim Marjeram, Technology Director at O’Hara, has been with the company for over 30 years and has played a key role through various transitions in tablet coating technology. With over 25 years at O’Hara, Paul Bovos, Vice President of Operations, manages projects seamlessly, thanks to the robust dedication of the entire team to servicing the equipment.

Brian takes pride in the structure and capabilities of his workforce: “We have divisions dedicated to process, installations, projects, instrumentation, and controls. Customers trust us, and we do everything possible to avoid any disruption to their production.”

Brian takes pride in the structure and capabilities of his workforce: “We have divisions dedicated to process, installations, projects, instrumentation, and controls. Customers trust us, and we do everything possible to avoid any disruption to their production.”

Spanning over 80,000 square feet, the O’Hara headquarters is in one of Toronto’s most prestigious and expensive real estate districts. At its core is the Innovation Center, a state-of-the-art facility that houses equipment ranging from R&D-scale models to full-scale commercial manufacturing systems. Here, customers are invited to run product trials ensuring a hands-on, satisfying pre-sale experience.

Spanning over 80,000 square feet, the O’Hara headquarters is in one of Toronto’s most prestigious and expensive real estate districts. At its core is the Innovation Center, a state-of-the-art facility that houses equipment ranging from R&D-scale models to full-scale commercial manufacturing systems. Here, customers are invited to run product trials ensuring a hands-on, satisfying pre-sale experience.

As part of its commitment to nurturing future talent and supporting industry professionals, O’Hara actively collaborates with pharmaceutical institutes worldwide. Most recently, the company installed a lab-scale coater at the Bombay College of Pharmacy and introduced advanced coating technology to students at K. M. Kundanani Pharmacy College and Sanjivani College of Pharmacy in India.

It is a common misconception that the continuous coating process necessitates a continuous feed of tablets from the tablet press. This technology allows manufacturers to coat all tablet batches continuously from the first tablet to the last, without the need to break down the batches into multiple ones. While batch coaters involve a time dependent process and are typically manually operated, continuous coaters are rate dependent, and recipe driven. As pharma manufacturers face increasing pressure to boost output and reduce costs, the continuous coating technology presents several benefits, such as:

It is a common misconception that the continuous coating process necessitates a continuous feed of tablets from the tablet press. This technology allows manufacturers to coat all tablet batches continuously from the first tablet to the last, without the need to break down the batches into multiple ones. While batch coaters involve a time dependent process and are typically manually operated, continuous coaters are rate dependent, and recipe driven. As pharma manufacturers face increasing pressure to boost output and reduce costs, the continuous coating technology presents several benefits, such as:

• reduction in product losses

• reduced in-process control

• significantly reduced carbon footprint

• reduction in capital costs

• reduction in labour costs

• significant reduction in utility consumption

• up to 85% operational equipment efficiency.

Brian O’Hara believes that continuous coating technology holds significant promise for the future of tablet coating. He emphasises that the shift towards continuous coaters is not only inevitable but also essential for tablet manufacturers.

According to Brian, the urgency for advancements in coating technology has never been greater, particularly in the light of rising operational costs and the high value of the formulation blends. By adopting continuous coating technology, manufacturers can alleviate numerous challenges and enhance operational efficiency.

According to Brian, the urgency for advancements in coating technology has never been greater, particularly in the light of rising operational costs and the high value of the formulation blends. By adopting continuous coating technology, manufacturers can alleviate numerous challenges and enhance operational efficiency.

While the industry has gradually transitioned from continuous coating systems to batch coaters, the move towards continuous coating technology will be swift and unavoidable. This evolution represents a critical step in progression to optimise the production process and ensure sustainability of manufacturing practices in the pharma industry.

As India accelerates toward the future of pharmaceutical manufacturing, O’Hara Technologies stances as a trusted partner with their continuous coaters, blending visionary leadership, proven technologies, and active industry engagement. With a footprint that now extends into academic institutions and industry forums across the country, O’Hara is not just shaping equipment, it is shaping the future of Indian pharmaceutical fineness.