In the glistening ambiance of success and camaraderie, the stage was set for an evening of unparalleled splendor and distinction as the maiden edition of Pharma Quality Excellence Awards 2024 unfolded in all its grandeur.

During the welcome keynote, Ms. Guneet Kaur Hayer, Managing Director of Eminence Group, illuminated her vision for the Pharma Quality Excellence Awards. With eloquence and passion, she underscored the significance of honoring the unsung heroes of the pharmaceutical industry. Ms. Hayer’s address resonated with the audience, emphasizing the importance of recognizing and celebrating excellence in pharma quality. Her words set the tone for an evening dedicated to acknowledging the invaluable contributions of those who uphold the highest standards in the field.

The ceremony commenced with the traditional lamp lighting ceremony, symbolizing the illumination of knowledge and excellence. Led by the esteemed Managing Director of Eminence Group, Ms. Guneet Kaur Hayer, and distinguished guests Mr. D.R Gahane, Jt Commissioner and Chief Controlling Authority, FDA Maharashtra, Mr. Prashant Sharma, CTO, Zydus Life Sciences, Dr. VG Nayak, Ms. Sarah Bresee, Managing Director APAC, Master Control, Mr. Vipul Doshi, Chief Quality and Compliance Officer, Zydus Life Sciences, Mr. RanjitBarshikar, CEO of QbD International; Mr. Shirish Belapure, Senior Technical Member of IPA; Mr. SM Mudda, Managing Director of Misom Labs; Dr. Rajiv Desai, Former VP of Lupin; and Dr. Damodharan M, Sai Life Sciences Ltd. lit the ceremonial lamp, marking the auspicious beginning of the night’s festivities.

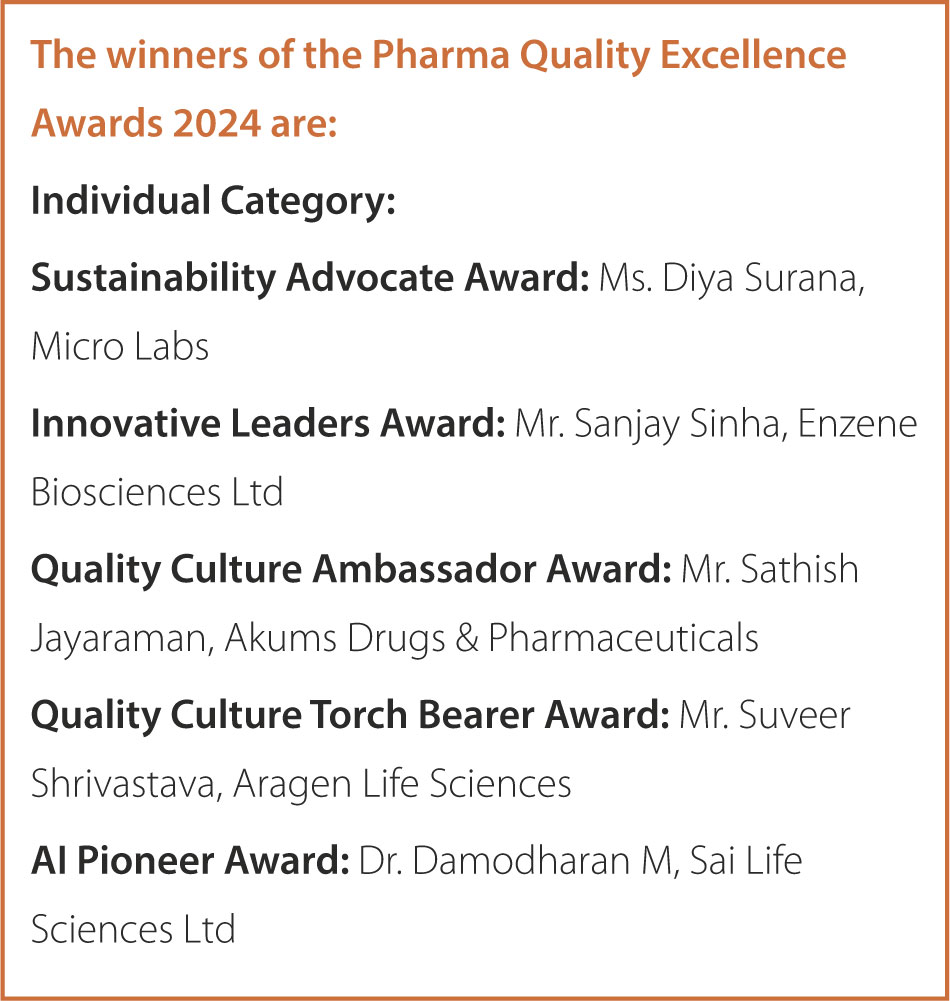

Amidst the backdrop of mesmerizing performances and heartfelt speeches, the event unfolded seamlessly, celebrating the visionary leaders and trailblazers of the pharm quality domain. From Individual Category to Organisational to Special Category awards, every accolade celebrated the relentless pursuit of quality and innovation.

Ms. Vrushali Negandhi, Head of Production and Research at Eminence Business Media, elucidated the meticulous methodology behind the Pharma Quality Excellence Awards 2024. She introduced the esteemed jury as the “Veracious Voices of Pharma,” underscoring their pivotal role in discerning excellence. Their collective wisdom guided the selection process, ensuring only the most deserving were honored. Ms. Negandhi’s address left the audience with a deep appreciation for the awards’ integrity and the esteemed jury’s discernment.

From the felicitation of the esteemed jury members to the enthralling Bharatnatyam performance, each moment was a testament to the spirit of innovation and excellence that defines the industry.

As the night progressed, the spotlight shone on the esteemed award winners, each one a beacon of inspiration and achievement in their own right.

Jury's Choice Awards –

Pharma Quality Leadership Award & Lifetime Achievement Award

The evening reached its crescendo with the Jury’s Choice Awards announcement, honoring the industry stalwarts whose contributions have left an indelible mark on the pharma quality landscape. With standing ovations and thunderous applause, the winners accepted their accolades, humbled by the recognition of their peers and colleagues. Dr. VG Nayak was awarded the Lifetime Achievement Award for his service of over 30 years. During this time, he was pivotal in four major organizations, shaping industry standards in operations, quality, R&D, and regulatory affairs. His leadership drives innovation and excellence.

Mr. Vipul Doshi received the Pharma Quality Leadership Award for his extensive contributions to the industry. He’s been a driving force in ensuring global regulatory compliance and fostering excellence and ethical practices. His expertise extends to project engineering, facilitating infrastructure development for APIs and drug products.

In a fitting finale, the stage came alive with a mesmerizing performance, leaving the audience spellbound and enthralled. As the curtains drew to a close, the air was filled with a sense of camaraderie and accomplishment, a testament to the collective spirit of excellence that defines the pharmaceutical community.

In her closing remarks, Ms. Guneet Kaur Hayer thanked all attendees for their unwavering support and participation. With a promise of continued collaboration and innovation, she bid farewell to an evening filled with memories of triumph, and celebration.

Articles

By Satish Desai

By Karan R Khairnar