Lubricate! Lubricate! Lubricate!

There’s a reason we use the phrase “well-oiled machine” to describe something that performs at ultimate efficiency. A properly lubricated tablet press runs smoother and more efficiently with less wear over time, and has significantly extended service life. Lubricating your tablet compression tooling reduces wear during use, and coating your tooling with protective oil during storage prevents rust.

Maintain and Repair Your Current Tooling with Polishing Equipment and Accessories

Proper tooling maintenance goes a long way, and by using different polishing methods you can buff out worn and eroded punch cup surfaces, remove burrs, and restore land to your punches. So before you decide to purchase a new set of tooling, contact one of our experts to learn how to rework your current set.

Use Multi-Tip Tooling Whenever Possible

The cost of an average set of multi-tip tooling is insignificant in comparison to the extensive costs of labor, tablet presses, and other tablet production expenses. Switching from traditional single-tip tooling to a six-tip configuration increases tablet output by as much as 500%, which allows manufacturers to reduce the number of tablet presses and operators needed to achieve equal output, substantially reducing overall operating costs. Contact a Natoli tooling expert to determine whether multi-tip tooling is right for you and your product

Regularly Inspect Your Tooling to Improve Product Quality and Reduce Waste

Regular tool inspection and management allow you to improve product quality and consistency, resulting in a reduction of “reject” tablets and wasted product. Combine the Natoli Laser Vision System (LVS) punch inspection device with the Tool Management II (TM-II) database software module to get the most powerful tool control system available. Visit natoli.com for additional information, to view photo galleries and video, to schedule a free webinar, or to download a free trial of the software.

Purchase Replacement Parts and Get More Life from Your Tablet Press

A new tablet press can cost more than a million dollars, so before you take the plunge and buy new, check to see if purchasing replacement parts for your current press is a better option for you. We carry over 300,000 replacement parts (including turrets) for most major makes and models of tablet presses, in-stock and available for next-day delivery! Not sure which part you need? Contact a Natoli representative today to help troubleshoot your specific issue and determine the parts you need.

Refurbish Your Outdated Tablet Press

If simply replacing a few parts isn’t enough, consider having your press refurbished. Our engineers will evaluate your press and help determine your needs, which can range from fixing minor issues to completely rebuilding your press to meet FDA regulations, add features such as automated touchscreen interfaces, and have it running better than new. The average cost of a complete rebuild can range between 25% and 50% of the cost of a brand-new press.

Invest in Your Employees

Having a well-trained, knowledgeable staff is critical to the success of any business, especially in this industry. One mistake by an unqualified press operator can severely damage a set of tooling, the tablet press, or both, which could end up costing tens of thousands of dollars or more. By investing in employee training, you’ll increase productivity, product quality, and employee retention. Natoli Engineering offers comprehensive tablet press and tooling training.

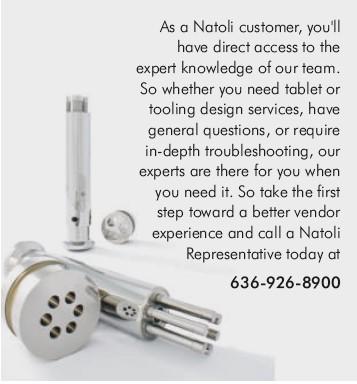

Work with Vendors You Know and Trust

Buying from smaller, less experienced vendors may get you cheaper pricing, but as the old adage goes, “you get what you pay for”. What those vendors don’t tell you is with cheap prices come cheap products and poor service. At Natoli, we pride ourselves on providing exceptional quality products with extraordinary service. Our experts have decades of industry experience and have authored technical articles for major industry publications, lectured at major universities and institutions around the world, and provided personal service time and time again to satisfied customers when no other company could.