DIGITAL FACTORY

Data-driven plant manager suite for improving production processes

The digitalisation of production processes refers to the integration of digital technologies into manufacturing. This shift from traditional to digital processes has had a significant impact on the way goods are produced, and has led to increased efficiency, flexibility, and competitiveness in multiple industries.

The use of digital technologies in manufacturing has made possible the implementation of Internet of Things (IoT) technology for real-time monitoring and control of production processes, supported by the extensive use of big data from production. By collecting and analysing large amounts of data, manufacturers gain valuable real time insights into their operations and make informed decisions about how to optimise their processes, such as by identifying bottlenecks on the shopfloor, introducing predictive maintenance in machinery to reduce downtime, and increasing productivity.

This data-driven approach has proven tremendously effective in powering the digital revolution and, conversely, gifting the companies which have adopted it with significant benefits.

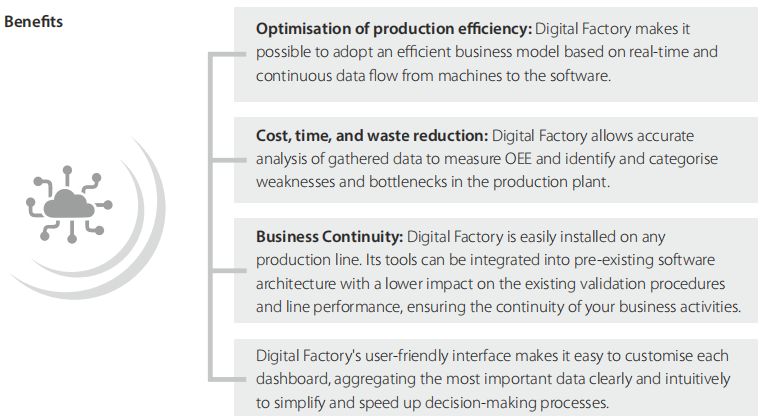

As a result, big data analysis has become a strategic asset for operational excellence and business competitiveness. A data-driven approach has helped drive the digital revolution and created significant benefits for business, including:

Agile decision-making: Effective data management and analysis can uncover actionable insights for strategic decisions and anticipating trends and challenges.

Beneficial effect on profitability and costs: Collecting, monitoring, and analysing data from production (e.g. availability, quality, efficiency, maintenance) leads to improved operations, which increases profitability and margins while lowering costs.

Improved productivity: Digitalisation of the production environment helps reduce the time and effort required to complete repetitive tasks.

To become a partner in digitalising production processes, Antares Vision Group, has developed Digital Factory, a data intelligence platform powered by AI to help companies enhance line efficiency and production quality, improve planning, and speed up agile decision-making.

Features

- Real-time data acquisition by connecting existing equipment to extract value from production lines.

- Real-time data visualisation to live-monitor production performance of lines and plants up to the corporate level.

- Instant data analysis that performs and combines multiple queries to reveal trends and data patterns.

- Automated smart alert system for event or time-based warnings.

- Escalation management in case of critical conditions, such a stopped line and decreased overall equipment effectiveness (OEE); the escalation path can be managed to accelerate the restoration to standard conditions.

- Self-customisable control panel for automated rule responses: When the batch stops, reports are automatically sent to the reference so additional controls such as email updates or alarm reports can be carried out.

Modularity

Digital Factory has six powerful modules for gathering, managing, and extracting production data:

The modules which are part of the Digital Factory solution are:

Traceability Module: Antares Vision’s L3 software solution for managing serialisation and aggregation.

Efficiency Module: Measures OEE to identify losses and waste by category and creates reports and analyses to provide clear, data-driven suggestions to solve issues related to product efficiency.

Plant Manager: Antares Vision Group’s manufacturing execution systems software to handle all plant operations, assets, resources, recipes, work orders, raw materials (linked with a warehouse management system).

Quality Module: Digitalisation of company documentation and management of supplier selection by collecting and linking rejects to a raw materials supplier.

Maintenance Module: Complete management and optimisation of maintenance activities, including creation and fulfilment of maintenance report templates (spare parts replaced, time to repair), analysis of machine failure and performance, and AI and machine learning support to manage predictive and prescriptive maintenance.

Maintenance Module: Complete management and optimisation of maintenance activities, including creation and fulfilment of maintenance report templates (spare parts replaced, time to repair), analysis of machine failure and performance, and AI and machine learning support to manage predictive and prescriptive maintenance.

Sustainability Module: Tracking different energy consumptions (e.g. water and other fluids, gases) within a plant to make recommendations on how to improve consumption and better comply with health, safety, and environment (HSE)policy.

This article is contributed by Antares Vision Group