Control of Genotoxic and Elemental Impurities

Control Strategy

A control strategy is a planned set of controls derived from current product and process understanding that assures process performance and product quality. A control strategy can include, but is not limited to, the following:

- Controls on material attributes (including raw materials, starting materials, intermediates, reagents, solvents, primary packaging materials);

- Facility and equipment operating conditions;

- Controls implicit in the design of the manufacturing process;

- In-process controls (including in-process tests and process parameters);

- Controls on drug substance and drug product (e.g., release testing).

There are 4 potential approaches to development of a control strategy for drug substance:

Option 1: Include a test for the impurity in the drug substance specification with an acceptance criterion at or below the acceptable limit using an appropriate analytical procedure.

Option 2: Include a test for the impurity in the specification for a raw material, starting material or intermediate, or as an in-process control, with an acceptance criterion at or below the acceptable limit using an appropriate analytical procedure.

Option 3: Include a test for the impurity in the specification for a raw material, starting material or intermediate, or as an in-process control, with an acceptance criterion above the acceptable limit of the impurity in the drug substance, using an appropriate analytical procedure coupled with demonstrated understanding of fate and purge and associated process controls that assure the level in the drug substance is below the acceptable limit without the need for any additional testing later in the process.

Option 4: Understand process parameters and impact on residual impurity levels (including fate and purge knowledge) with sufficient confidence that the level of the impurity in the drug substance will be below the acceptable limit such that no analytical testing is recommended for this impurity (i.e., the impurity does not need to be listed on any specification).

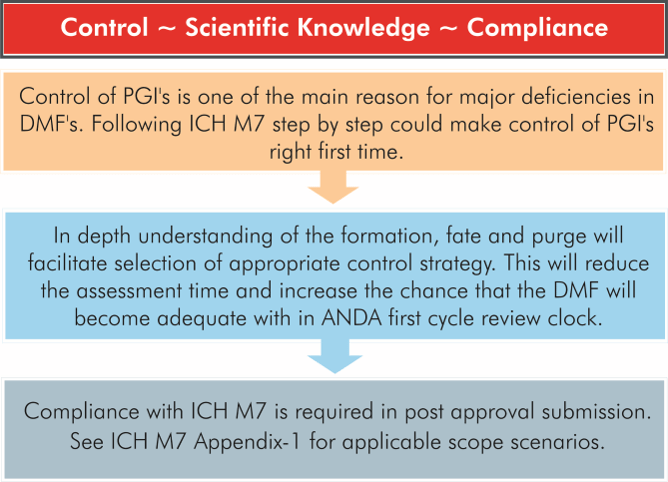

Without compromising drug substance quality, select best control option to minimize the assessment time.

A control strategy that relies on process controls in lieu of analytical testing can be appropriate if the process chemistry and process parameters that have an impact on the levels of mutagenic impurities are understood and the risk of an impurity residing in the final drug substance above the acceptable limit is determined to be negligible. In many cases, justification of this control approach based on scientific principles alone is sufficient. Elements of a scientific risk assessment can be used to justify an option 4 approach.

The risk assessment can be based on physicochemical properties and process factors that influence the fate and purge of an impurity, including chemical reactivity, solubility, volatility, ionizability, and any physical process steps designed to remove impurities. The result of this risk assessment might be shown as an estimated purge factor for clearance of the impurity by the process.

Option 4 is especially useful for those impurities that are inherently unstable (e.g., thionyl chloride that reacts rapidly and completely with water) or for those impurities that are introduced early in the synthesis and are effectively purged.

In some cases an Option 4 approach can be appropriate when the impurity is known to form, or is introduced late in the synthesis; however, process-specific data should then be provided to justify this approach.

Where industry can improve?

Sub type of potential genotoxic impurity (PGI) related deficiencies and recommendations:

PGI not addressed: Provide a complete list of PGIs from reagents/starting materials/in-situ or isolated intermediates/by-product through simple comparison with a known alerting functionality, and through searches of published information such as CCRIS.

Control not sufficient: For Option 3, Acceptance criterion above the TTC, demonstrate process capability at the proposed level with spike/purge data.

Ames (Q) SAR data not sufficient: Quality data of AMES test, which can be performed per ICH S2(R1) and OECD 471 Bacterial Reverse Mutation test (Ames test). Quality data of (Q)SAR, from ICH M7 compliant software.

TTC not acceptable: Calculate with MDD and Acceptable intakes per RLD information.

M7 exemption not Acceptable: M7 Exemption applies to drug substance and drug product intended for advanced cancer indications; or, drug substance itself Genotoxic at therapeutic concentrations.