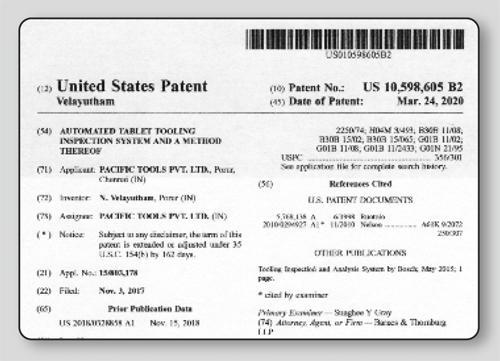

N. Velayutham is a technocrat and director of Pacific Tools Pvt Ltd., associated with the industry since 1987. He has rich experience in the manufacturing of pharmaceutical machines and tooling. He is a pioneer in developing new technologies in the tablet tooling and compression machine and holds a US patent in his name for automatic tablet tool laser inspection system.

N. Velayutham is a technocrat and director of Pacific Tools Pvt Ltd., associated with the industry since 1987. He has rich experience in the manufacturing of pharmaceutical machines and tooling. He is a pioneer in developing new technologies in the tablet tooling and compression machine and holds a US patent in his name for automatic tablet tool laser inspection system.

Pacific Tools Pvt Ltd, one of the leading manufacturers of tablet tooling, has become the first Indian pharmaceutical machinery manufacturer to bag a US patent for its innovative automatic tablet inspection system, TIIM 100. On this exceptional achievement, PHARMA Machines & Technology caught up with its technocrat director N. Velayutham for an exclusive interview.

Q&A

Q.Congratulations to you and your team on becoming the first Indian pharma machinery manufacturer to be awarded a US product patent. Before getting to that, let’s start discussing the impact of the Covid pandemic in your business and also in the pharmaceutical industry?

A.Indian pharma companies have contributed a lot in saving the lives of Covid infected people around the world, and we take pride in being associated with the pharmaceutical industry. Overall, the Indian pharmaceutical industry has grown during this pandemic, so we also did not face difficulties due to a lack of orders.

We have two full-fledged manufacturing facilities, one in Chennai and another in Mumbai, which also helped us in managing operations in the most efficient way. Since both these units faced lockdown in different periods, we could meet our customer commitments and achieve marginal sales growth in 2020-2021.

Q.The fast-changing pharmaceutical industry calls for newest technology solutions. How equipped are you in meeting them?

A.Every year the technology in the industry is being upgraded. Indian pharmaceutical industry leads the global market.

To keep pace with global trends we have focused on upgrading our manufacturing infrastructure, processes, and quality. In addition, we have invested heavily in manpower development and competence.

Today, all our products are designed and manufactured to meet global standards using the latest technology. All our machines meet 21 CFR part 11 standards and CE certification.

Q. What’s the nature of competition from global suppliers and how do you face it?

A. Global competition is inevitable in this modern era. We, at Pacific, find this as an opportunity to learn, upgrade and compete with them, both in the domestic market as well as in the international market.

As far as tablet tooling is concerned, we are certainly capable of competing with the international manufacturers in every aspect. We also have innovative products like TIIM 100 which is the world’s best in that category, and we received a US patent last year. This product was showcased in Achema, Germany, and was well received and appreciated by global customers.

Q. What was the motivation for the innovation of TIIM 100?

A. From the inception of Pacific Tools in 2002, we have always been attempting to find innovative solutions to fill the gap between the requirement of our customers and the currently available technology. We were the first in India to manufacture 100 KN pre-compression tablet presses, instrumented tablet presses for R&D, and tablet tools made of premium steel and novel coatings.

In 2006 itself, we observed that there was a need for better equipment for the inspection of punches and dies and we developed an inspection system using contact measurement instruments. But we were not satisfied with the outcome and the project was shelved.

Our interest was rekindled when we came across the availability of robust measuring instruments like laser sensors using non-contact technology. In 2014, a team of our engineers started working relentlessly to develop a simple, time-saving, 21 CFR part 11 compliant and fully automatic tooling inspection system. After their hard work of 20 months, we achieved success in realizing our goal in 2015 and applied for the patent, and also launched the product.

We got the US patent in 2020 and also await the Indian patent. It is in the final stage with the authorities and we expect to receive it very soon.

Q. What has been the response of your customers after launching TIIM 100?

A. We launched our tooling inspection system in 2017, and it received a very good response from our customers across the country. Within a year we installed our inspection system TIIM 100 in five of the top 10 pharmaceutical companies in India, and most of these users placed repeat orders for their facilities in different locations. We are overwhelmed by these responses and are now motivated to launch TIIM 100 in the US market as well.

Q. You did mention your tablet presses. How well Pacific’s tablet presses are being accepted in the industry?

A. Both our R&D and pilot tablet presses are a huge success in India. We have installed over 100 fully instrumented compression machines across India and many of our customers stayed with us and repeated the orders. The quality, the robust construction, and user-friendly software are the highlights.

Q. What are your projections for the future?

Q. What are your projections for the future?

A. We started Pacific Tools with the mission of becoming the world leader in tablet tooling. Now we have become one of the largest and most reputed tablet tooling manufacturers in India. Our tooling quality is of global standards and is well accepted in big pharma companies in developed countries too.

We are a leading player in many countries with a strong customer base and are continuously expanding to newer markets. All our products are well accepted in the international market and we are looking forward to partners for marketing our products into newer areas.

As far as the technology is concerned our R&D team is relentlessly working on developing new machines and also in improving our present product quality and performance. Besides we are open to collaboration or joint venture with international companies to upgrade our technology.

We anticipate India playing a still bigger role in the global pharmaceutical industry as most of the Indian pharma companies are in expansion mode and our government supports the pharma industry as a whole. The future looks very bright and we are expanding our capacities for all the products anticipating increased demands.