One of the leading pharma company in India had similar problem. But this was not a deterrent for them to completely automate their end of line operation. They also had to include product serialization and aggregation.

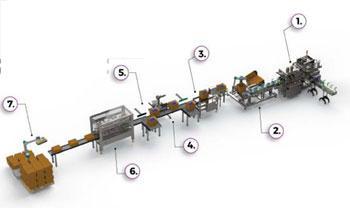

Clearpack came up with a unique solution which can very well fit in the space provided. Solutions were based on robotics which helped optimize the footprint of the equipment. Clearpack jointly worked with a leading track and trace solution provider to put in place a complete line, taking care of all critical interface points between different partners of the project. This helped customer getting a completely engineered and tested solution from a single source without worrying about integration.

Benefits to customer:

- Fully automated solution with no manual intervention

- 100% Track and Traceability integration to the manufacturing process and visibility in the entire supply chain

- Overcoming challenges of unstable bottles after application of PL (Patient Information Leaflet)

- Collaborative operation

- Easy integration with the existing line

- Low operating costs,

- Safe & hygienic packing

- Faster RO!

- Small Footprint

- Flexible and durability of machinery for long run.

- Real time monitoring of OEE

- Accurate results and fast output DD